IS-205

Cone shape

Various traverse implemented

Each winder has a separate motor which allows each cylinder to be

operated independently. Each of the 4 spindles can be implemented

on different traverses independently.

Features

MAXIMIZING IN CONVENIENCE In line with user’s requirement, it enables user friendly operation by control of Nos,

of spindle with maximum flexibility

STAND ALONE TYPE DRIVING MOTOR It makes independent operation as every winder having its own driving motor

SPEED CONTROL BY INVERTER Spindle RPM can be smoothly controlled by inverter device

MINIMUM DOFF TIME Fully automated bobbin exchanging operation from supplying bobbins to its transferring, exchanging

and yarn connection within a least amount of time to make it possible to minimize labor costs as well as increase productivity

DIGITAL COUNTER Target winding length is effectively controlled by pre-set winding parameter on the digital counter

DROPPER MOTION Yarn breakage is instantly detected by dropper motion for immediate remedial actions

PRESS ROLLER Motion guide enables a highest quality in relation to the wound shape on cones which is a highly sought-

after quality in the industry

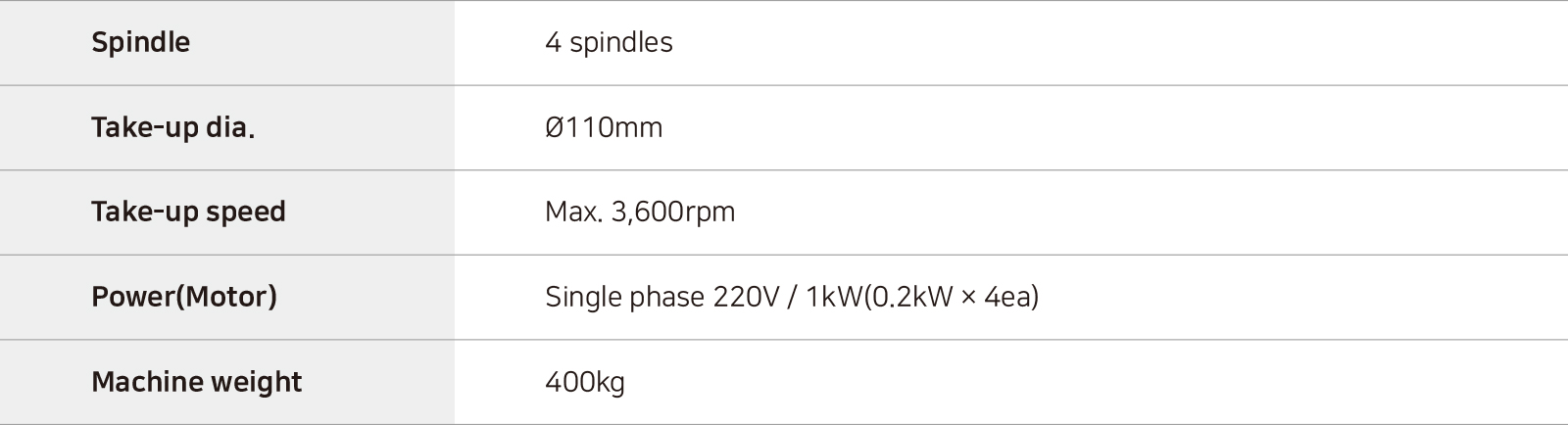

Specifications