IS-103C

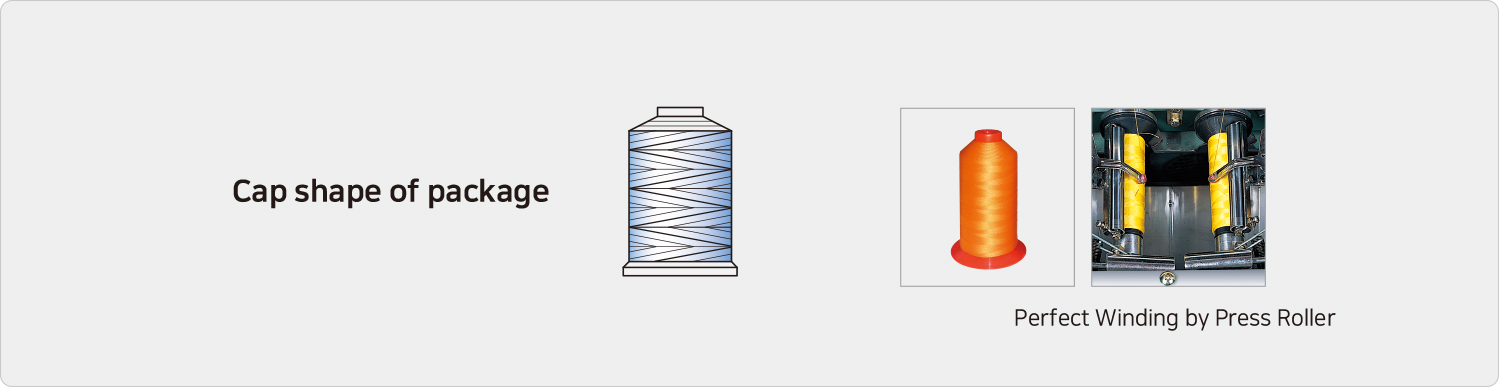

Cap shape

High quality winding for cap type

Dropper motion makes it possible to detect thread breakage instantly and

accurately, and thus it maintains a regular shape of the thread on a cap and enables winding to a highest standard; as a result producing highly competitive products.

Features

MINIMUM DOFF TIME Fully automated bobbin exchanging operation from supplying bobbins to its transferring, exchanging

and yarn connection within a least amount of time to make it possible to minimize labor costs as well as increase productivity

DIGITAL COUNTER Target winding length is effectively controlled by pre-set winding parameter on the digital counter

DROPPER MOTION Yarn breakage is instantly detected by dropper motion for immediate remedial actions

PRESS ROLLER Motion guide enables a highest quality in relation to the wound shape on cones which is a highly sought-

after quality in the industry

SPEED CONTROL Possible to regulate acceleration and reduction of the spindle speed according to thread type by inverter

installation

※ Option : Speed device by oil motor / Heater for waxing

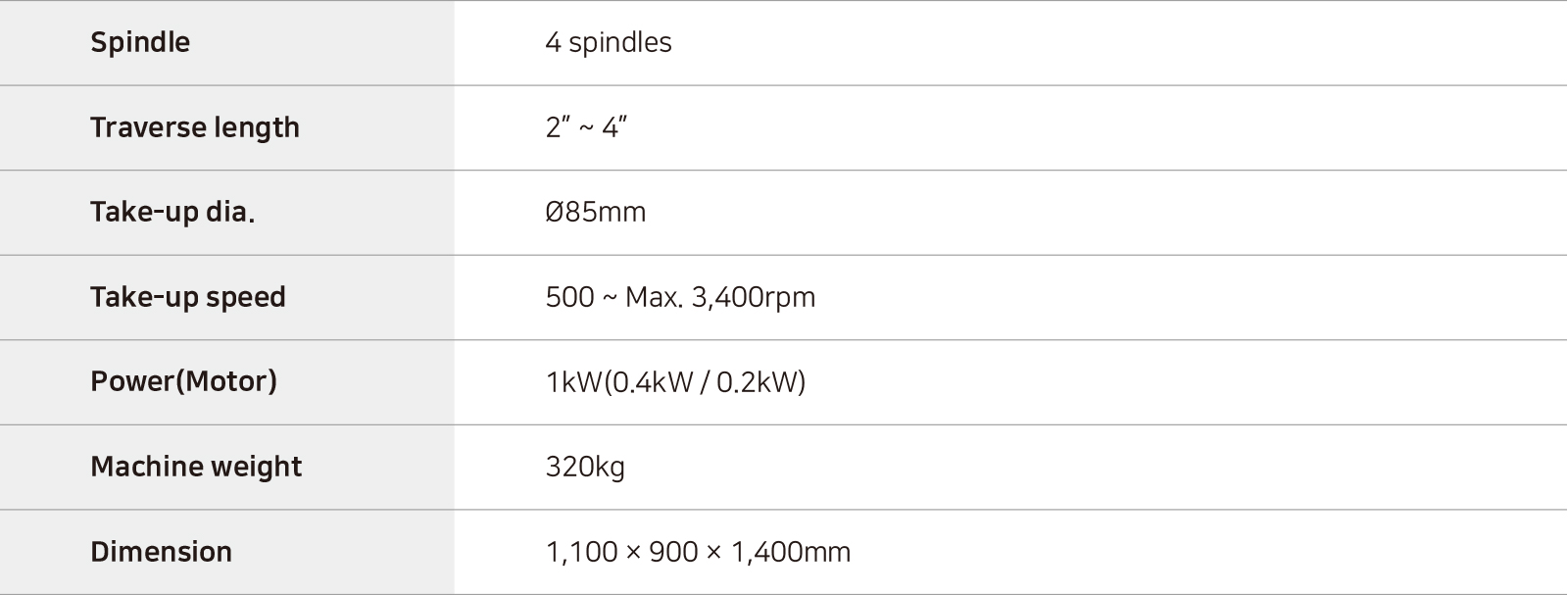

Specifications